Description

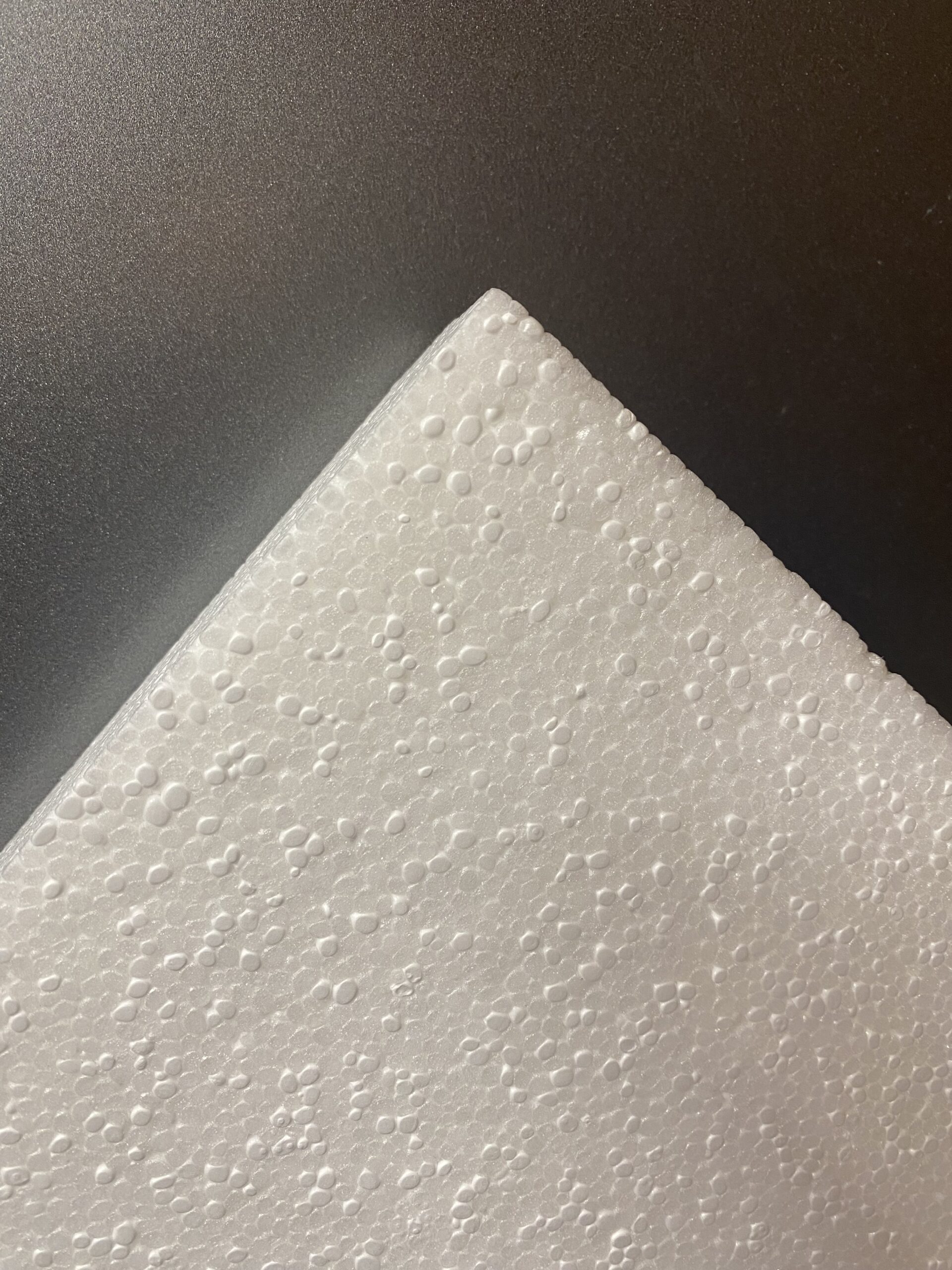

BIOfoam e-pla sheet 860x570x40mm

BioFoam is an expanded poly lactic acid foamed sheet

Applications

The properties of BioFoam make it suitable for isolation purposes and making sandwich panels for interior applications. It is also suitable for mock-ups or prototyping models.

Processing

Cutting Hot wire cutting (oscillating or stationary wires) is recommended. Temperature of the wires should be about 200–300 °C.

Technical information

Typical physical properties

RAW material value unit test method

Monomer level <0,1 % Gas chromatography

Main bead size distribution 0,8-1.6 mm Image analyser

End product 35 KG/m3

Heat conductivity (l10) 0,035

(W/mK) EN 12667

Shrinkage

Above 50 degrees Celcius is it possible that the PLA biofoam will shrink.

Suitainability

Biofoam E-PLA can be recycled. It is biobased and biodegradable.

Compostability of BioFoam has been tested by OWS in Belgium according to EN 13432. The pictures below show a sample at the start of the trials (left), after 26 weeks of cold composting (middle) and after four weeks of composting at industrial conditions (right). Cold composting is done at lower temperature (30°C) than the industrial process (60°C).

EN 13432 requires that materials do not contain harmful chemicals. Next to that this standard concerns the disintegration of materials. This means that they should fall apart into smaller pieces, which can be converted into CO2 and water. Disintegration is studied in a pilot scale test. Biodegradation is studied on lab scale by measuring CO2 release over time. The result of such a test is shown in the graph below in which BioFoam is compared to a reference material (cellulose). As one can see the biodegradation is initially slower, but the speed increases towards the end of the test and ultimately the material is fully converted within 60 days.

Reviews

There are no reviews yet.